84 Lumber uses two Potain self-erecting cranes to tackle tight-space apartment build

- By combining the abilities of the Potain Igo T 130 and Igo T 99, the company was able to overcome severe space limitations in an urban center without needing to reposition the cranes mid-project.

- The cranes’ remote-controlled operation was crucial to the success of constructing a six-story apartment building in Pittsburgh, enabling the precise placement of large, prefabricated components.

- Manitowoc’s ongoing support — including parts, service, and training — helped both Stephenson Equipment and R.R. Miller Construction keep the project on track from planning through execution.

Two Potain self-erecting tower cranes played a prominent role in the construction of a new six-story, 267-unit apartment building in the U.S. city of Pittsburgh’s hot-spot neighborhood of Lawrenceville. Set along Butler Street, the project is part of a broader effort to revitalize the area’s former industrial footprint. The building is designed to introduce new housing and street-level activity to a compact urban site near the riverfront.

With limited staging space in an active urban area, the construction team faced real logistical challenges — especially during the wood-framing phase. A Potain Igo T 130 and an Igo T 99 provided an efficient solution, offering both the reach and maneuverability needed to stay on schedule without disrupting the surrounding area.

The Installed Sales Division of 84 Lumber was responsible for the lifting work, with materials supplied from an 84 Lumber retail location. Framing contractor R. R. Miller Construction rented the cranes from Stephenson Equipment, which also coordinated a third-party operator for the project.

“Our part included the wood framing on the top four levels, with the lower levels being concrete and steel,” said Steven Rider, a commercial install manager at 84 Lumber. “The T 130 was brought in first, followed by the addition of a Potain Igo T 99 to support the later phases of construction. This dual-crane setup allowed both machines to operate simultaneously with the necessary clearance and coverage across the site.”

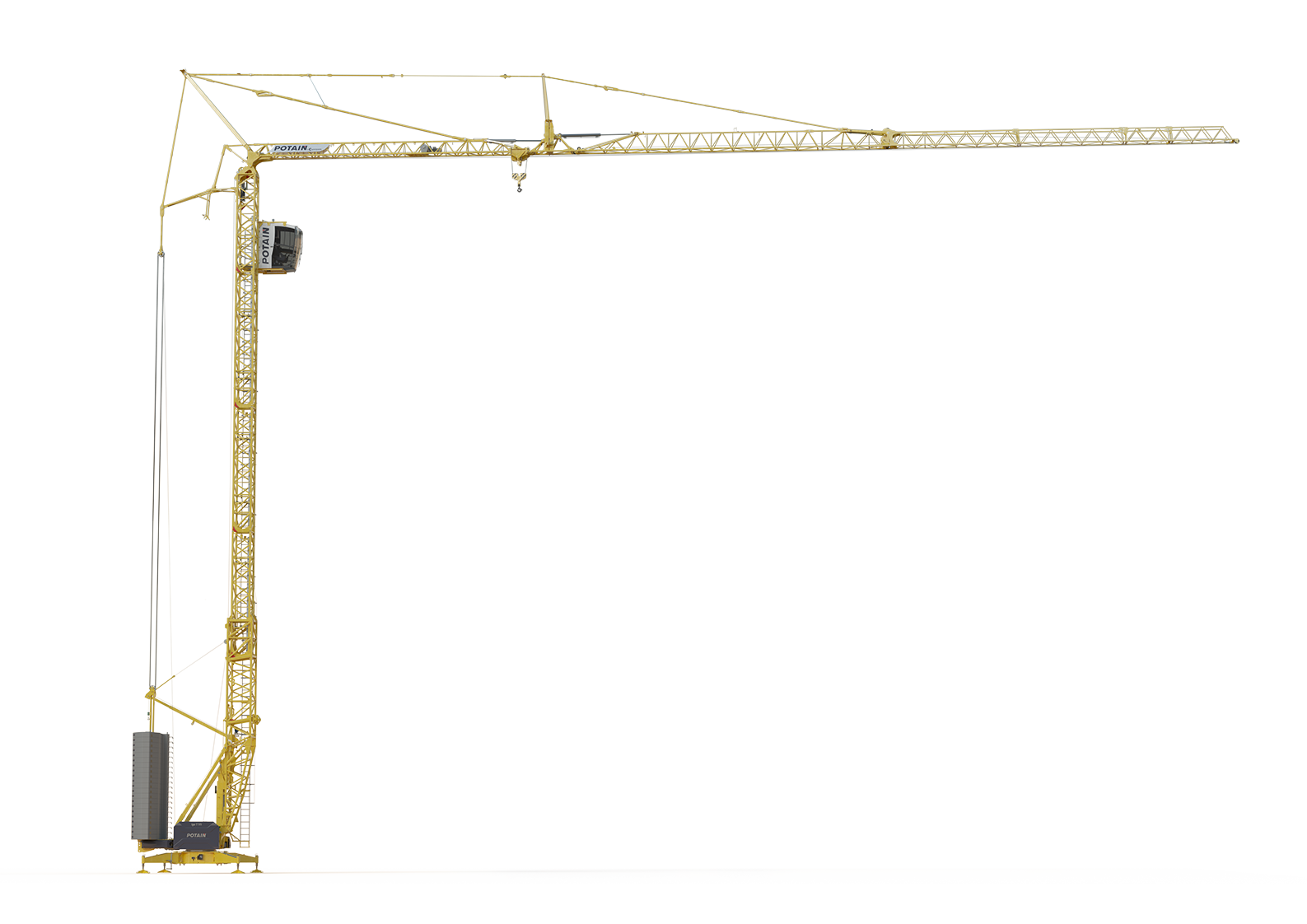

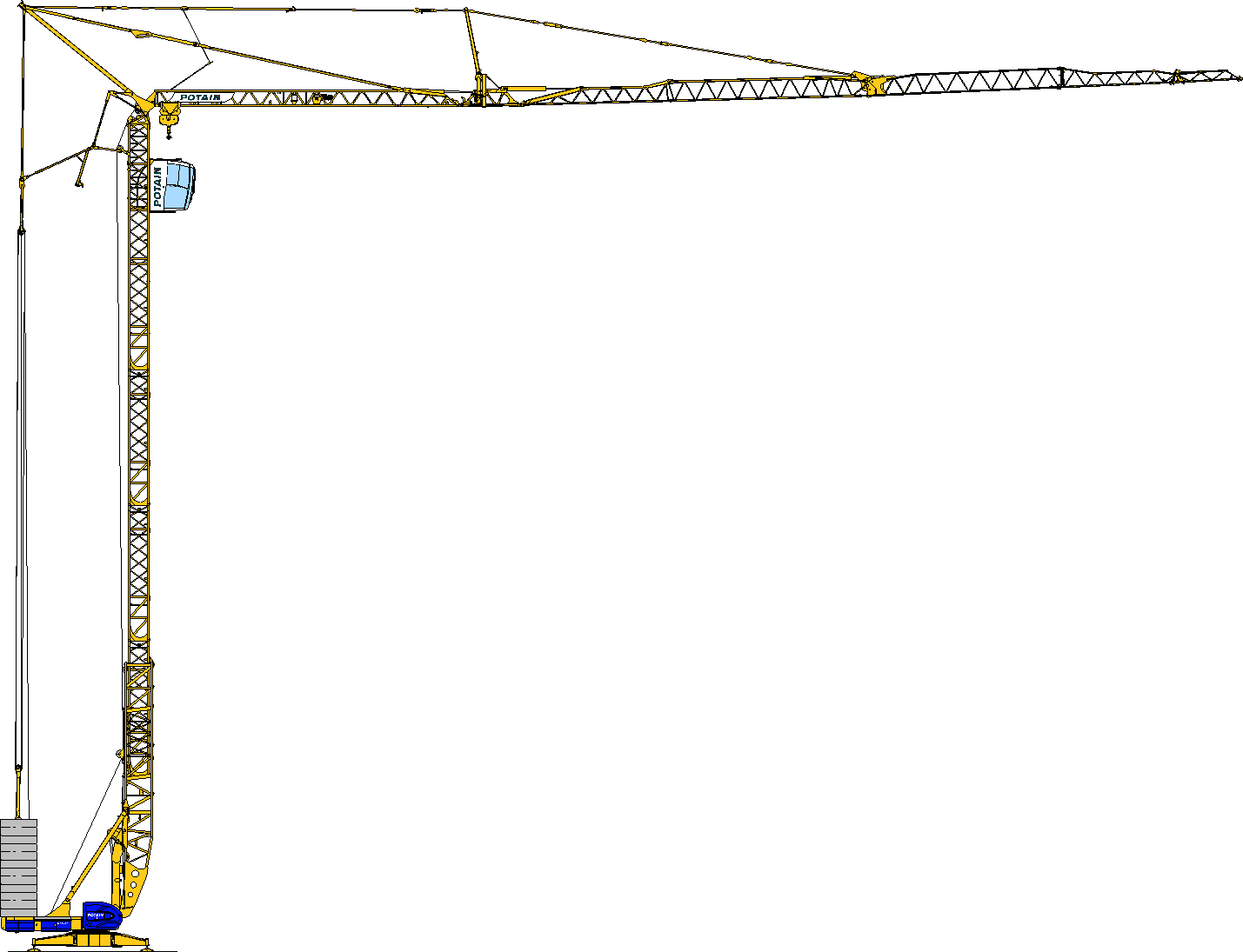

The Igo T 130 was erected with two additional mast sections, giving it a hook height of 113 ft, with the full 164 ft jib. The Igo T 99 was set up with three additional mast sections, providing a hook height of 126 ft and a 157 ft jib. The T 130 was first erected along Butler Street, a main traffic route with very little clearance from the traffic lane.

“The original plan was to move it to the inside corner of the building, but since we were only 20 ft off the property line, the adjoining property owner wouldn’t allow us to set outriggers on his side. So, we moved the crane to a secondary location that wasn’t as well-suited for covering the site,” Rider explained. “That’s why we brought in the T 99. Between the two cranes, we were able to cover everything and erect the entire wing of the building without moving the T 130 again.”

The cranes were used to lift pre-assembled wall panels, floor and roof trusses, loose lumber, and sheeting needed for construction. Given the tight conditions and the availability of crane access, other contractors on site also relied on the cranes to move their materials. Load weights ranged from a few hundred pounds up to 2.4 USt per lift, with lift heights ranging from 80 ft to 90 ft. The loads were easily handled with the T 130’s 8.8 USt capacity and the T 99’s 6 USt capacity.

The cranes were operated exclusively via remote control, allowing the operator to position themselves wherever they had the best view of the rigging process. Two-way radios were used to coordinate the precise placement of loads on the upper levels of the building. This setup helped maintain smooth and efficient operations despite the site’s extremely tight working conditions. Framing began on November 11, 2024, and continued through mid-June 2025.

Throughout the project, both Stephenson Equipment and R.R. Miller Construction relied on Manitowoc’s support infrastructure — from parts and service availability to hands-on training. That behind-the-scenes backing helped keep the cranes running smoothly and the timeline on track, even in a complex urban environment. While Stephenson provided guidance and technical coordination, Manitowoc’s continued investment in service and support played a quiet but essential role in the project’s success.

“Without Stephenson Equipment’s help in selecting the right crane sizes and identifying suitable erection sites, the project could have turned into a disaster,” Rider said. “On jobs like this, the timeline is everything, and the team at Stephenson Equipment was always quick to respond whenever issues or questions came up.”

CONTACT

Chris Bratthauar

Sr. Director, Marketing

Manitowoc

T +1 717 593 5348

chris.bratthauar@manitowoc.com

POTAIN

Self-Erecting Cranes

Fast, agile and easy to operate, the self-erecting cranes are especially suited for small constructions sites. The Potain self-erecting cranes ranges are the most innovative to make transport, accessibility, erection, dismantling and servicing the most efficient ever for the user. With the widest range on the market, the Potain self-erecting cranes include the Evy, Hup, Hup M, Igo, Igo M and Igo T ranges.