Range-topping Potain cranes debut on prestigious Saudi Arabia resort project

- A Potain MCT 1105 and Potain MCT 1005 are working on Sindalah, a luxury island resort under construction as part of the NEOM infrastructure project in northwest Saudi Arabia.

- Both units belong to NFT, which has one of the largest Potain crane fleets in the world.

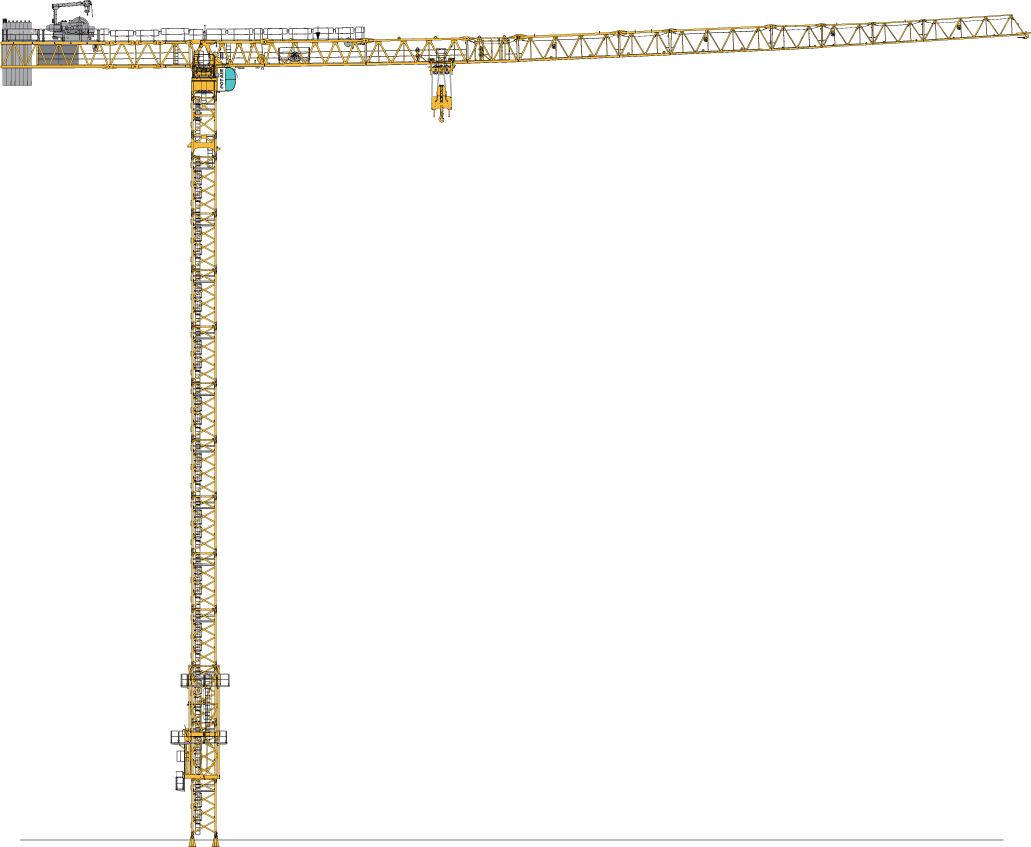

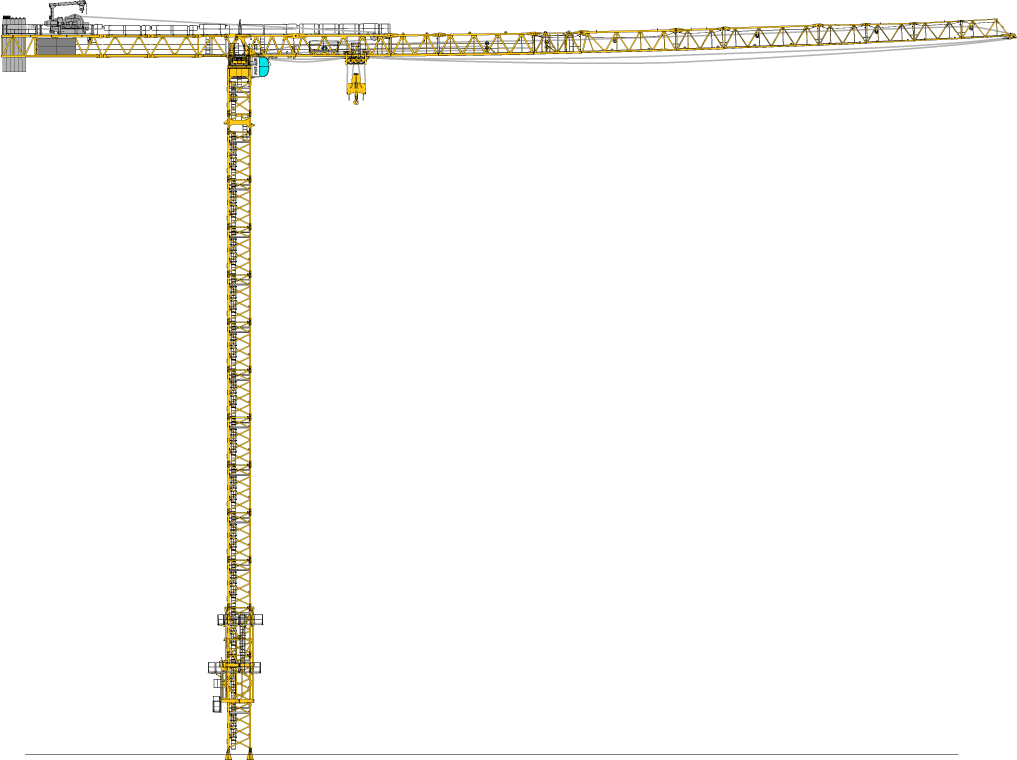

- The MCT 1105 is the largest ever topless tower crane from Potain, and the MCT 1005 is the second largest.

NFT Group has purchased two landmark Potain tower cranes and immediately shipped both to a high-profile tourist destination under construction in Saudi Arabia as part of the vast NEOM development. One of the cranes is an MCT 1105, the largest topless tower crane from Potain, and the other is one of the previous largest models, an MCT 1005.

Long-time Potain partner NFT Group boasts one of the world’s most extensive tower crane fleets, including several of the giant MD 1100 – a forerunner to the MCT 1105. It was many years of positive experience with the MD 1100 that prompted the company’s interest in the MCT 1105 and MCT 1005. The NFT Group was an integral part of the 'Voice of the Customer' process involving Manitowoc's new cranes, with the end results being extremely impressive, said Nawar Al Zahlawi, business development manager at NFT Group.

“We had a lot of success with the MD 1100 which has such strong lifting capacities across the entire working radius. When we first had discussions with Manitowoc about potential evolutions for the model, we were glad to support the projects. I’m pleased to say the MCT 1105 and MCT 1005 have surpassed our expectations. The load charts are even better than expected and the topless design means they can work seamlessly alongside other cranes. They also have monobloc mast sections which make them quicker to erect.”

The cranes are scheduled to work onsite for nine months on Sindalah, a luxury Red Sea Island resort, and part of Saudi Arabia’s NEOM project. Using large capacity tower cranes was the only option for the jobsite, owing to limited space and the fact there are no accessible routes for mobile or crawler cranes on the 840,000 m2 island. The timeframe is tight for construction too, so a precast design is being used to speed up the build time. This means the cranes have to place concrete modules of up to 20-30 t. Given these constraints, the two Potain heavyweight cranes proved perfect for the job.

Both have been configured with 50 m jibs for the project, although they can accommodate up to 80 m. The MCT 1005 is working with a 43.1 m height under hook, while the MCT 1105 has a 63.1 m height under hook. Maximum possible freestanding height for both is 69.7 m. Both cranes can also lift a maximum of 50 t, however, the MCT 1005 will lift 8 t at its 80 m jib radius, while the MCT 1105 can lift an impressive 11 t at the same radius. When working with a 50 m jib, as on the Sindalah project, the MCT 1005 will lift 21.5 t at the jib end, and the MCT 1105 will lift 22.8 t.

“Not only are the MCT 1105 and MCT 1005 very powerful cranes that meet most lifting demands, they were also a joy for our erectors to install. Witnessing their enthusiasm for the job and Potain’s new design developments brings us great satisfaction,” Al Zahlawi concluded.

CONTACT

Elena Morozova

Marketing Manager, Middle East Africa and CIS

Manitowoc

T: +971 4 886 26 77

elena.morozova@manitowoc.com

POTAIN

Top-Slewing Cranes Asia

Potain, the world leader of the tower crane now sells a range of models perfectly adapted to each type of construction. These products are based on the latest technologies and are associated with a complete set of equipment.