Tailored for the tides: Potain Lift Solutions delivers a tower crane built for the future

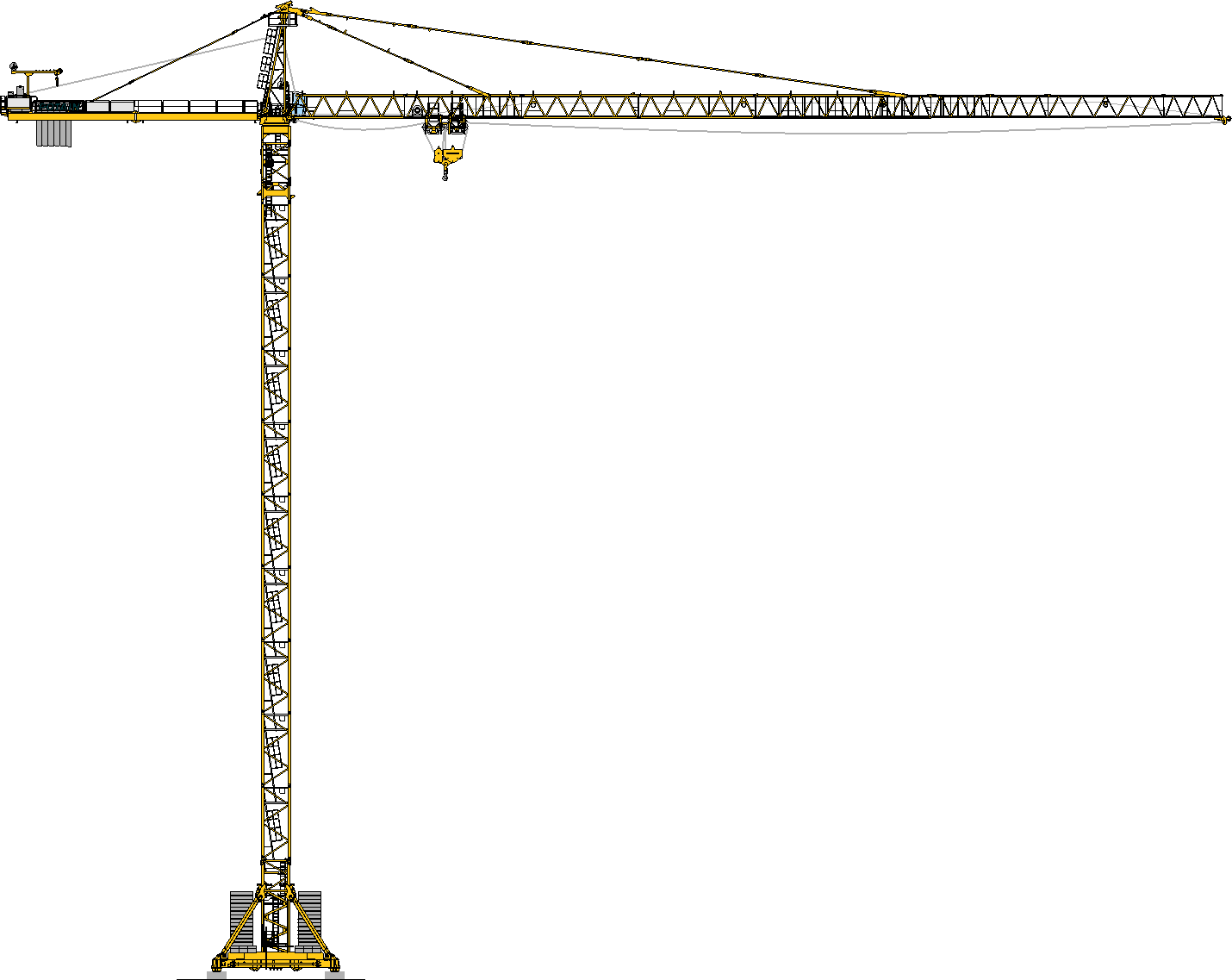

- The custom-built Potain MD 689 M25 features a new type of gantry traveling unit, seaside corrosion proofing, and digital connectivity.

- The crane is a significant investment for the port to grow its capacity and facilitate the loading of larger ships with higher capacities.

France’s Port of Nantes (Nantes Saint-Nazaire Port) received a major upgrade with the addition of a new Potain MD 689 M25. The crane facilitates the loading of larger ships with greater air draughts and increased capacities. It has been operating since March at the port’s naval maintenance and repair quay, replacing a crane that had been in operation since 1960.

Potain Lift Solutions provides analysis, product design, and consultation to customers seeking to optimize crane performance in specific applications or for those undertaking particularly demanding or challenging projects. The division collaborated with the port to tailor the crane to its particular needs and the local working environment. It was erected on a gantry that interfaces directly with the Potain Crane Control System (CCS) to travel across 170 m of rails, covering all three of the port’s dry docks.

The traveling gantry is the first on a Potain crane equipped with frequency inverter drives (and the drives are also integrated into the CCS). This delivers smooth, stepless motion along the tracks and excellent lifting performance. It also offers onboard assistance, particularly when paired with the Potain CONNECT™ digital platform, for real-time remote diagnostics, machine operation alerts, and remote actions.

“Lifting operations in ports have always been dynamic and demanding, with very high economic stakes,” said Sylvain Brunet, Lift Solutions business project manager. “For Nantes Saint-Nazaire Port, the requirements of the industry and the needs of our customers led us to develop an even more robust and innovative solution.”

The MD 689 25 was set up with permanent double reeving, providing a maximum lift capacity of 25 t when the jib is at 26 m, and 7.6 t when the jib is extended to its maximum of 75 m. For its working location, the crane was treated with paint to withstand the highly corrosive portside environment, meeting the C5-H standard under ISO 12944.

Other customizations included specially designed access and dedicated lighting. This features a lighting system operated from the control station that can be dimmed to avoid interfering with ground operations. There are also work cameras on the trolley and portal, as well as a communications system featuring in-cab microphones and speakers, an external loudspeaker, and channel encryption.

With the investment in its customized Potain tower crane and traveling system, the port has equipped itself to grow its business in the future:

“All that remains is to wish this machine a long life, just like its predecessor,” Brunet said.

To learn more about Potain Lift Solutions click here.

CONTACT

Dominique Leullier

Marketing Director Europe

Manitowoc

+ 33 4 72 18 21 60

dominique.leullier@manitowoc.com

POTAIN

Top-Slewing Cranes

Top-Slewing cranes are the large construction sites most strategic equipment for productivity. Whether on large infrastructure, high rise jobsites, crowded urban areas or wide open sites, they make it possible to hoist and distribute loads high and far. The Potain brand is a global leader with its multiple ranges of topless cranes, luffing jib cranes and large hammerhead cranes that can also be customized to match special applications.