Unique and Challenging Potain MDT 809 Installation for Borgo Roma Hospital Construction Project in Verona, Italy

CEER Res Omnia, a long-standing Potain partner, has successfully completed the complex installation of a Potain MDT 809 tower crane at the Borgo Roma Hospital construction site in Verona. The crane will be a pivotal component of the hospital’s retrofitting project scheduled to continue through 2028.

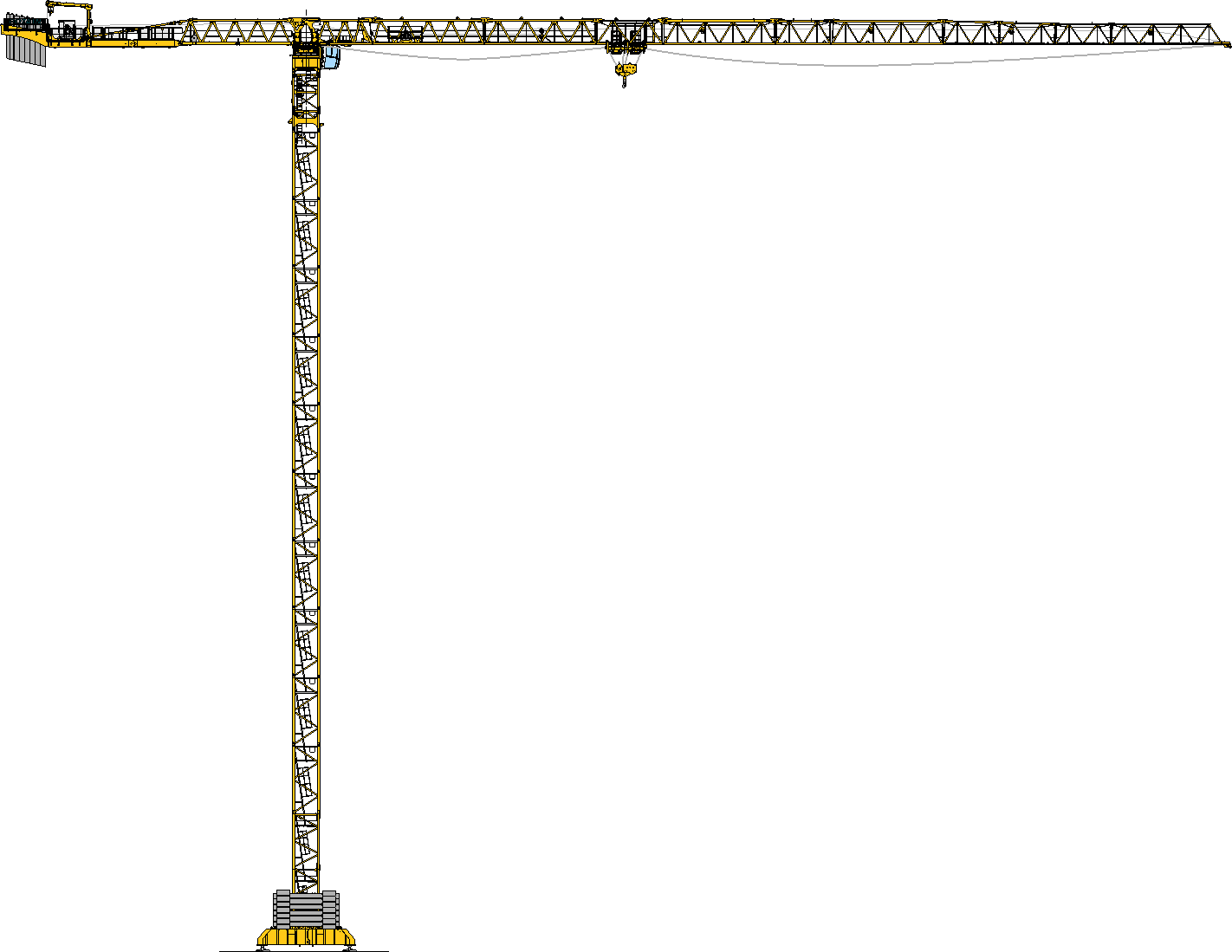

pulvinar CEER Res Omnia mounted the tower crane on a lattice structure approximately 44 meters above ground level. The crane was configured with 20 meter of masts and a 45 meter jib. The MDT 809, among the most powerful models in the Potain tower crane range, offers a maximum lifting capacity of 40 tons, with a 20-ton capacity at the jib tip, making it ideally suited for the demanding lifting requirements of this project.

A critical component for the installation was the design and construction of a metal lattice structure capable of supporting the crane while also enabling the crane to be repositioned across four distinct locations during the project. This system was engineered by CIMOLAI, an industrial group specializing in large-scale steel fabrication, utilizing a custom designed metal trolley. The crane’s stability throughout each phase was meticulously analyzed by Manitowoc’s Lift Solutions department, in collaboration with Gianluigi Consolaro, Service Director for Manitowoc in Italy, and Vincenzo Bassi, Owner of CEER Res Omnia.

"This operation fully reflects CEER Res Omnia’s philosophy, which approaches every project with a focus on innovation, safety, and professionalism, “said Vincenzo Bassi, owner of CEER Res Omnia. “Owning and managing machines of this scale allows the company to maintain complete control over every operational phase—from planning to commissioning—offering our clients excellent service for any lifting requirement."

The Potain MDT 809 will lift and position metal frameworks, reinforcement elements, and structural materials essential to the consolidation and seismic enhancement of the hospital complex.

Assembly operations began in mid-September under the coordination of Imola Gru, another long-standing Potain partner. The installation was completed in approximately four working days. Despite challenging logistical conditions and a severely restricted workspace, the technical team executed each phase with precision and on time. Sequential truck organization ensured progressive unloading and assembly, optimizing both efficiency and safety.

Luca Salomoni, team leader of the assembly crew, said "This was a demanding yet highly rewarding assignment. Installing a crane of this magnitude on a lattice structure at rooftop level is an uncommon undertaking. The logistical constraints, limited space, and need for absolute precision presented significant challenges. The collaboration among all parties was exceptional, and witnessing the crane completed and rising above the skyline was a gratifying culmination of our efforts."

CONTACT

Dominique Leullier

Marketing Director Europe

Manitowoc

T +33 4 72 18 20 20

dominique.leullier@manitowoc.com

POTAIN

Top-Slewing Cranes

Top-Slewing cranes are the large construction sites most strategic equipment for productivity. Whether on large infrastructure, high rise jobsites, crowded urban areas or wide open sites, they make it possible to hoist and distribute loads high and far. The Potain brand is a global leader with its multiple ranges of topless cranes, luffing jib cranes and large hammerhead cranes that can also be customized to match special applications.