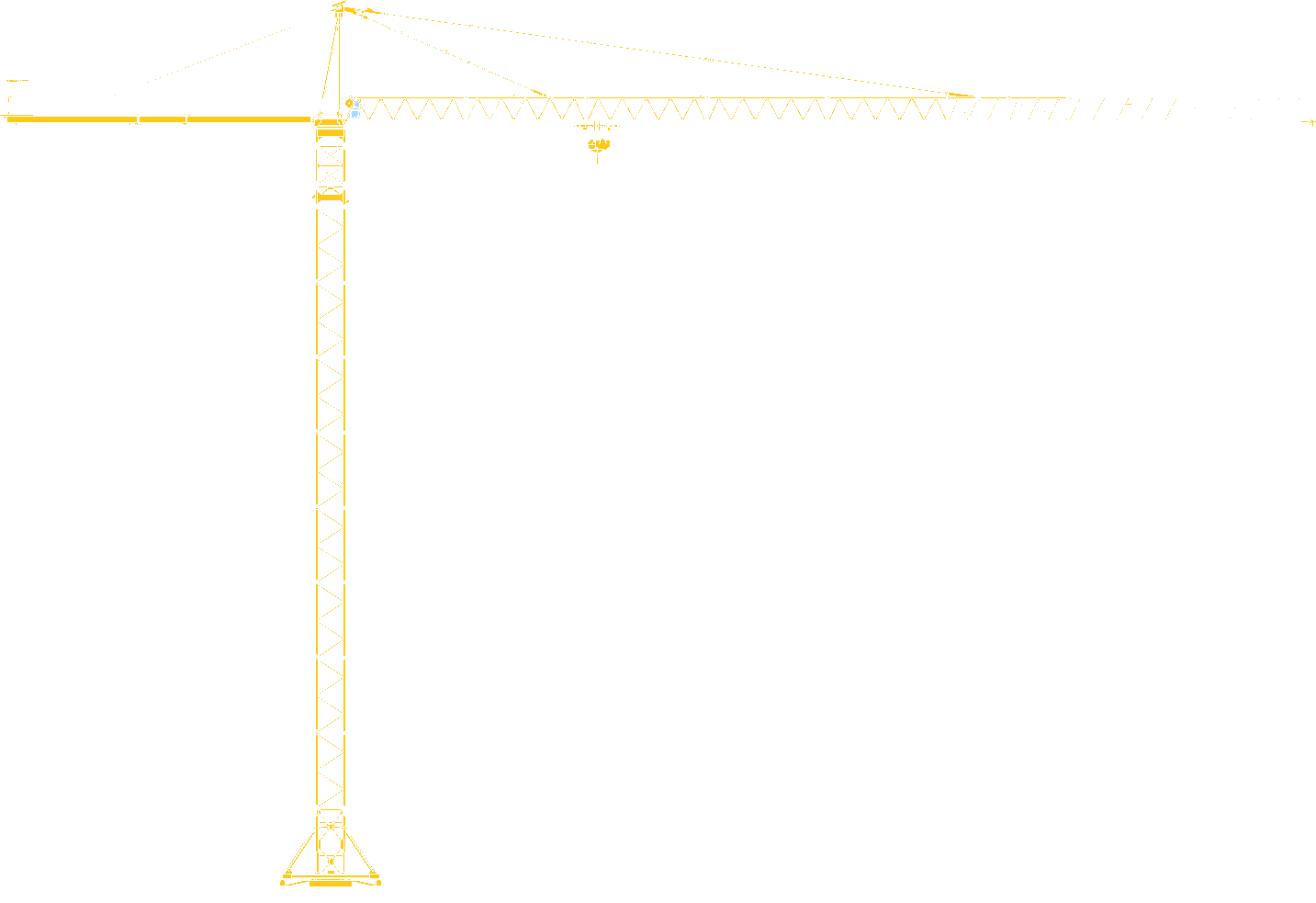

Reinforced mast: K850 2.45 m or round R 2.5 m

The frequency variation mechanisms (lift distribution orientation) allow the following circumstances:

- The regulation and control of the motor can be adapted to the machine's features notably height jib length and the load being hoisted: the behaviour of the crane while in operation is adapted to its configuration.

- Acceleration and deceleration for the machine and the crane operator are optimized: the crane structure is protected over the long term.

- Deceleration phases can limit the use of brakes. Brakes can be dropped at zero speed. This protects the crane structure over the long term.

- The crane operator can interact with the deceleration curves (it is possible to operate against orientation with Optima+). This allows the machine to be adapted to operating habits.

- The technician can quickly establish detailed diagnostics on the mechanisms thanks to the various menus on the variation panel (reading parameters meters) permitting a simple fast and efficient dialogue between man and machine.

- Inrush current can be reduced.

- Consumption can be reduced.

The MD 610 combines numerous innovations designed to reinforce safety and simplicity during assembly:

- The auxiliary winch used to ready the counter jib and jib cables considerably reduces assembly time. It also serves to mechanise the arm on the 25 t version.

- The large platforms and designated access distinctly improve and secure working conditions for lifting personnel.

- Every crane component is equipped with anchoring points for safe handling.

The next-generation Ultra View cab meets all the requirements for the crane operator to work safely in a comfortable ergonomic environment.

Extremely spacious it also provides excellent visibility of the construction site thanks to its 9 m² glass surface.

It comes with state-of-the-art equipment and a highly functional layout that allows the operator to personalise his space:

- Auto-regulated climate control upholstery

- Dialog Visu II indicators (display area showing information to assist in operation: immediate range permitted range height suspended load permitted load time wind haul)

- Front window wipers side window wipers sun visor

- Storage table electrical outlets

Key Advantages

- Fastest winch in its class: 270 hp for a maximum load of 40 t 532 m cable winding capacity

- Auxiliary winch standard for assembling cables

- Jib assembly possible in 1 2 or 3 parts. Maximum weight during assembly can be limited to approx. 16 t

- Comfortable access for assembly and maintenance

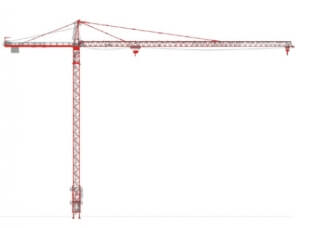

Enlarge image

Enlarge image