Six years of Potain cranes at ITER power plant construction site

- Since 2014 a total of seven Potain cranes have been working on one of the world’s largest nuclear fusion reactor construction sites – the ITER project in the south of France.

- Contractor Dodin Campenon Bernard, part of VINCI Construction, says the expertise provided by Potain has ensured efficiency and productivity throughout the life of the project.

- The cranes will be progressively dismantled by January 2021.

Since the first concrete pouring at the end of 2014, a total of seven Potain cranes have successfully completed the civil engineering and concreting works for the new generation ITER nuclear power plant.

After the acquisition of the six cranes in 2014 by contractor Dodin Campenon Bernard, part of VINCI Construction, several new cranes were gradually installed on the site for work annexed to the construction of the reactor, or for concrete work on all of the one hundred buildings now present on the site.

After disassembling the MDT 308 crane last September from the center of the bioshield for the reactor containment, and the MD 175 on the park for the civil works and the framework of the main building, the second phase of construction began, including the finishing work.

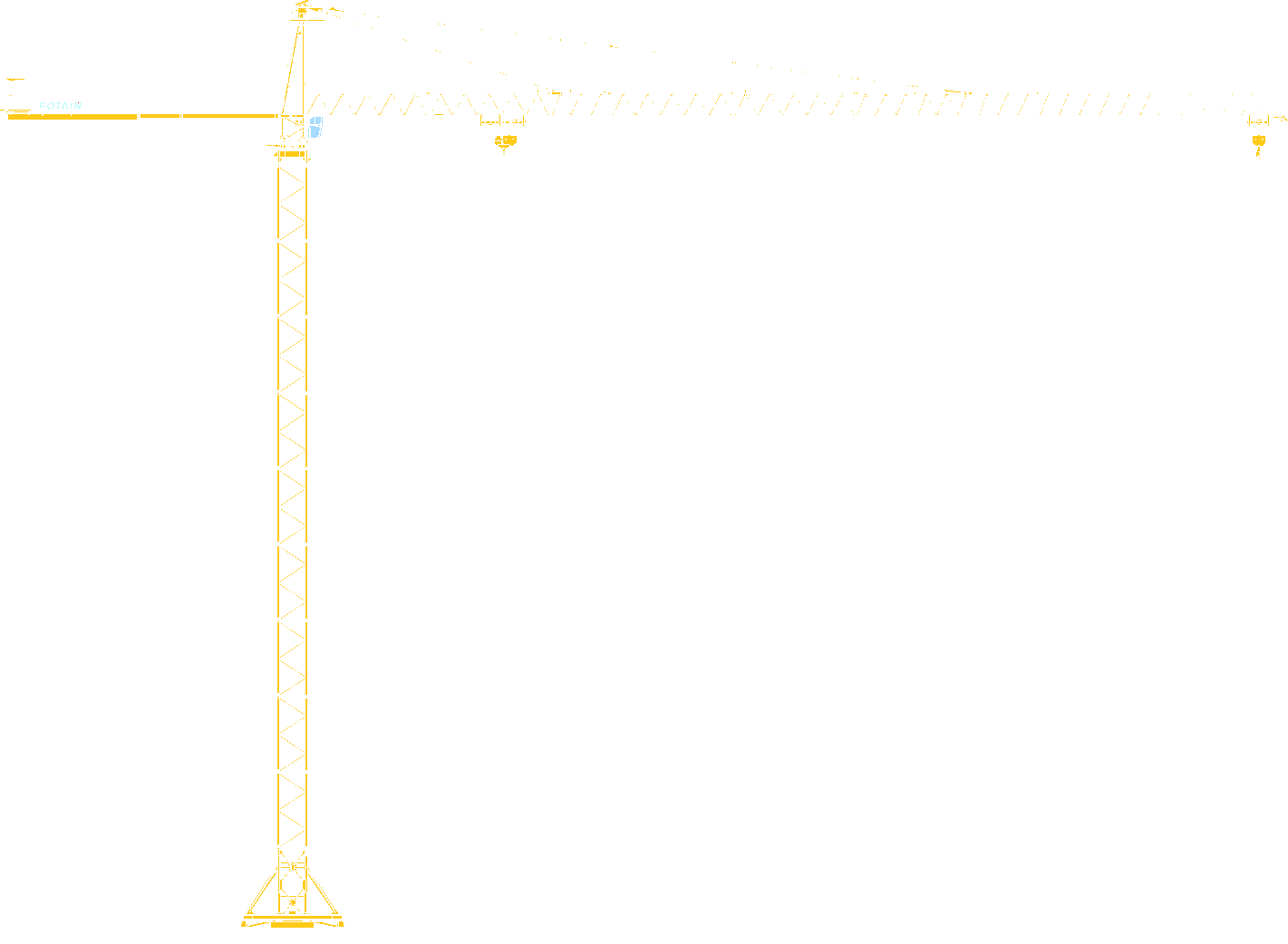

It is on this second phase that the Potain cranes and new machines have begun the last stages of construction. Today, four cranes are still constructing the buildings around the reactor – an MD 610, MD 485, MD 560 and an MDT 368.

The cranes have worked for five years pouring the concrete that will be necessary to contain the reactor, as well as assembling more than one million components, lifting steel profiles that range from 50 mm to 250 mm thick. These will house the systems necessary for the operation of the ITER Tokamak device, where nuclear energy will be produced.

Since the concrete pouring ended, the cranes on site have been used to install the metal structures of the buildings. The main seven-story concrete building will be 120 m long and 80 m wide. There will also be 16,000 t of rebar, 150,000 m3 of concrete and 7,500 t of steel in the structure.

MDT 389 joins the fleet

Most recently, an MDT 389 equipped with Manitowoc’s CCS control system joined the fleet of Potain cranes already on site. The crane was installed on a 96 m rail to manage the reinforcement and formwork fleet, with logistical support for concreting.

“We chose the largest of the Potain topless cranes in 2016, the MDT 389, for its lifting capacity of 16 t., , We installed the crane on an additional production station measuring 10,000 m2 to speed up the production of the necessary reinforcement and the logistics of the formwork on site. Still in place, it continues the mission in an area outside the site,” said Laurent Moustraire, material director for Dodin Campenon Bernard.

Since 2014, only Potain cranes have been used in the construction of the ITER site. Of the seven tower cranes in use, whether bought or rented, the primary challenge has remained the same — ensuring the reliability and performance of the machines. For the contractors dedicated to the construction of this new generation nuclear fusion reactor, the Potain cranes were a strategic choice.

Outstanding service and engineering support

Beyond the confidence in the Potain cranes, recognized for over 90 years, Manitowoc Crane Care services have brought an essential advantage to the contractors with comprehensive and advanced service and support since the start of construction.

Thanks to the dedicated teams of the Vitrolles service agency, contractors have 24/7/365 access to parts as well as operations by technicians for troubleshooting when problems arise, putting the cranes back into service as quickly as possible.

The value of Manitowoc Crane Care was justified very quickly when it became known that the project to construct a nuclear fusion reactor for ITER in the south of France will cost nearly €18 billion. It was also important to the contractor to benefit from reliable engineering expertise, ensuring the cranes were optimally installed and the lifting solutions were adapted for each task.

"What we also particularly appreciated throughout the project was the technical expertise provided by the Potain engineering teams,” Moustraire said. “Whether it was the study to place the MDT 308 in the center of the Tokamak on the raft, or to find anchoring solutions for the MD 560 and MD 485, which were on foundations overlapping galleries, each time the Dardilly Lift Solutions teams found technical solutions, and even anticipated constraints that we had not envisioned.

“It is very appreciated on a complex site that cannot afford unpleasant surprises. In general, the attention paid to our needs throughout the process, from the definition of the cranes to their assembly, and the expertise and flexibility shown by Manitowoc made our lives easy. This strengthened our confidence throughout the duration of this project.”

The ITER project started more than 10 years ago, and the concrete construction that began in 2015 with the installation of the first cranes, is designed to demonstrate the production of large-scale electrical energy. Ultimately, this installation, made up of one hundred buildings covering an area of 42 ha, should become the largest energy research project in the world. The remaining cranes on site will be phased out by January 2021.

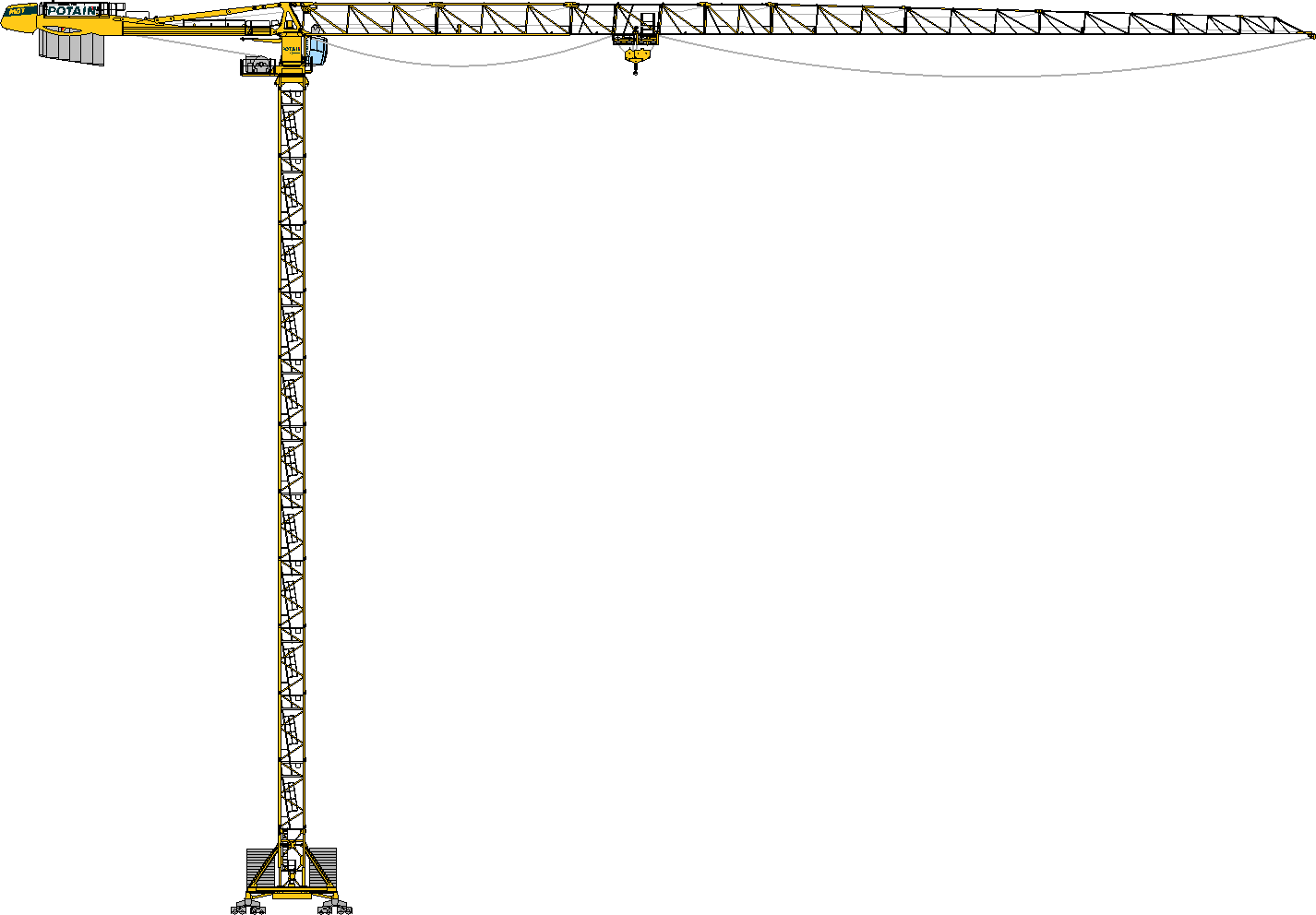

Image 1: The Potain MDT 368, MD 560, MD 610 and MD 485 on the job to complete the main building after dismantling the MDT 308 in the central Bioshield.

Image 2: The MDT 389 joined the fleet to manage the park logistics.

CONTACT

Cristelle Lacourt

Manitowoc

T +33 472 182 018

cristelle.lacourt@manitowoc.com

Enlarge image

Enlarge image

Enlarge image

Enlarge image

POTAIN

Top-Slewing Cranes

Top-Slewing cranes are the large construction sites most strategic equipment for productivity. Whether on large infrastructure, high rise jobsites, crowded urban areas or wide open sites, they make it possible to hoist and distribute loads high and far. The Potain brand is a global leader with its multiple ranges of topless cranes, luffing jib cranes and large hammerhead cranes that can also be customized to match special applications.