Large fleet of 17 Potain cranes emerge on Milan’s skyline to build MIND, a new €4.5 billion innovation district

- A public-private partnership between developer Arexpo and real estate giant Lendlease has started work on MIND, which could become one of Europe’s most advanced urban areas, in terms of sustainable design on a large scale.

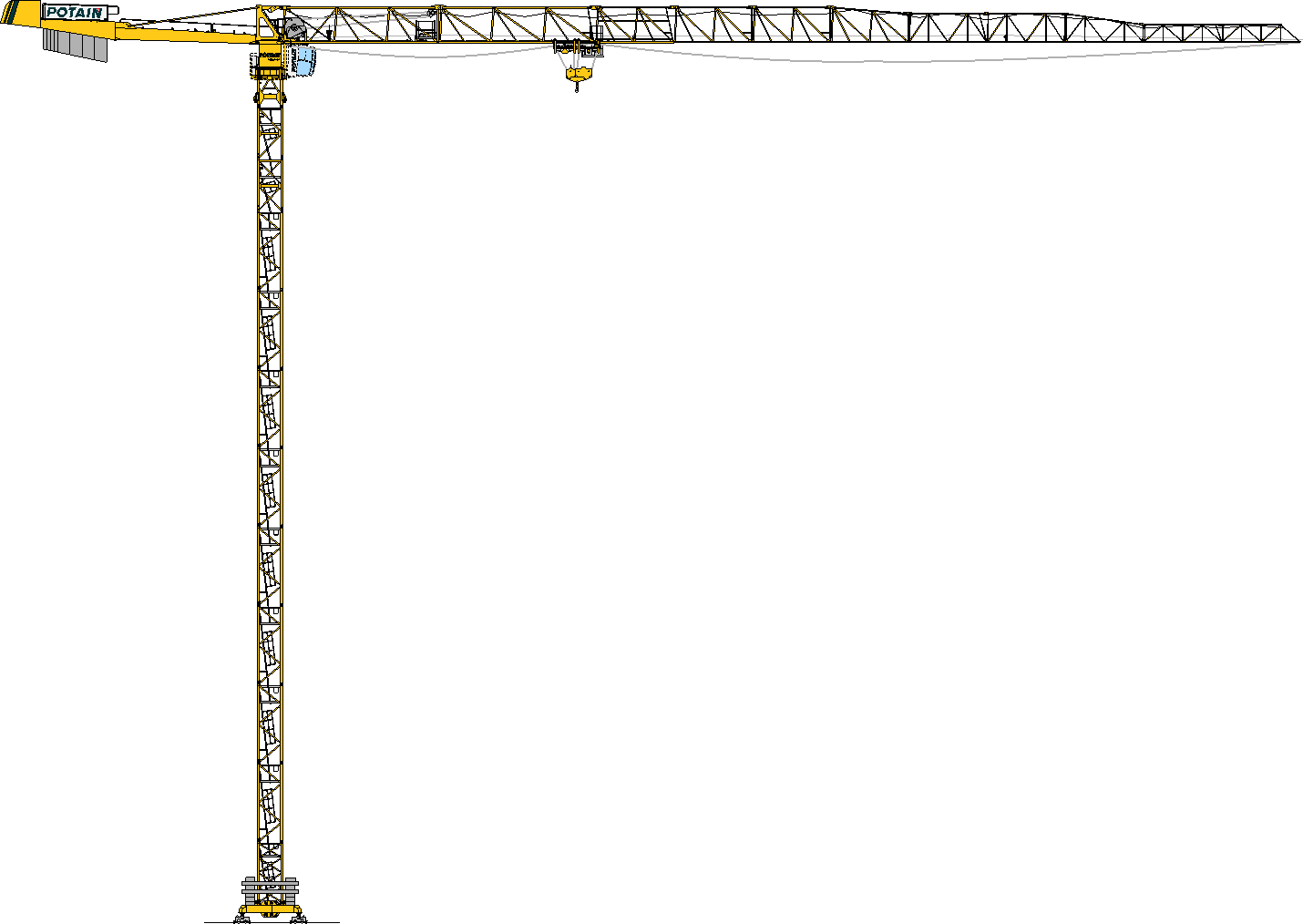

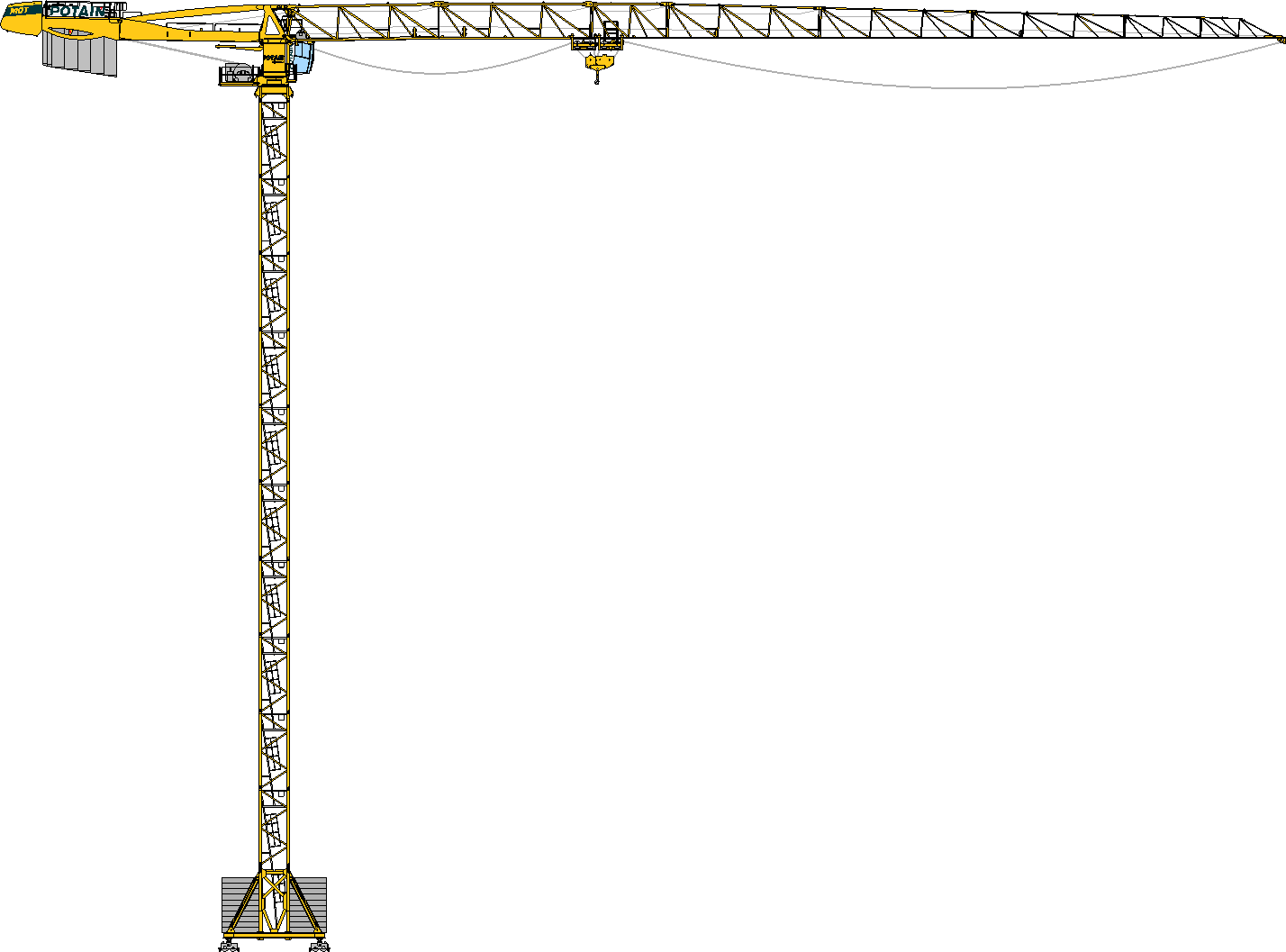

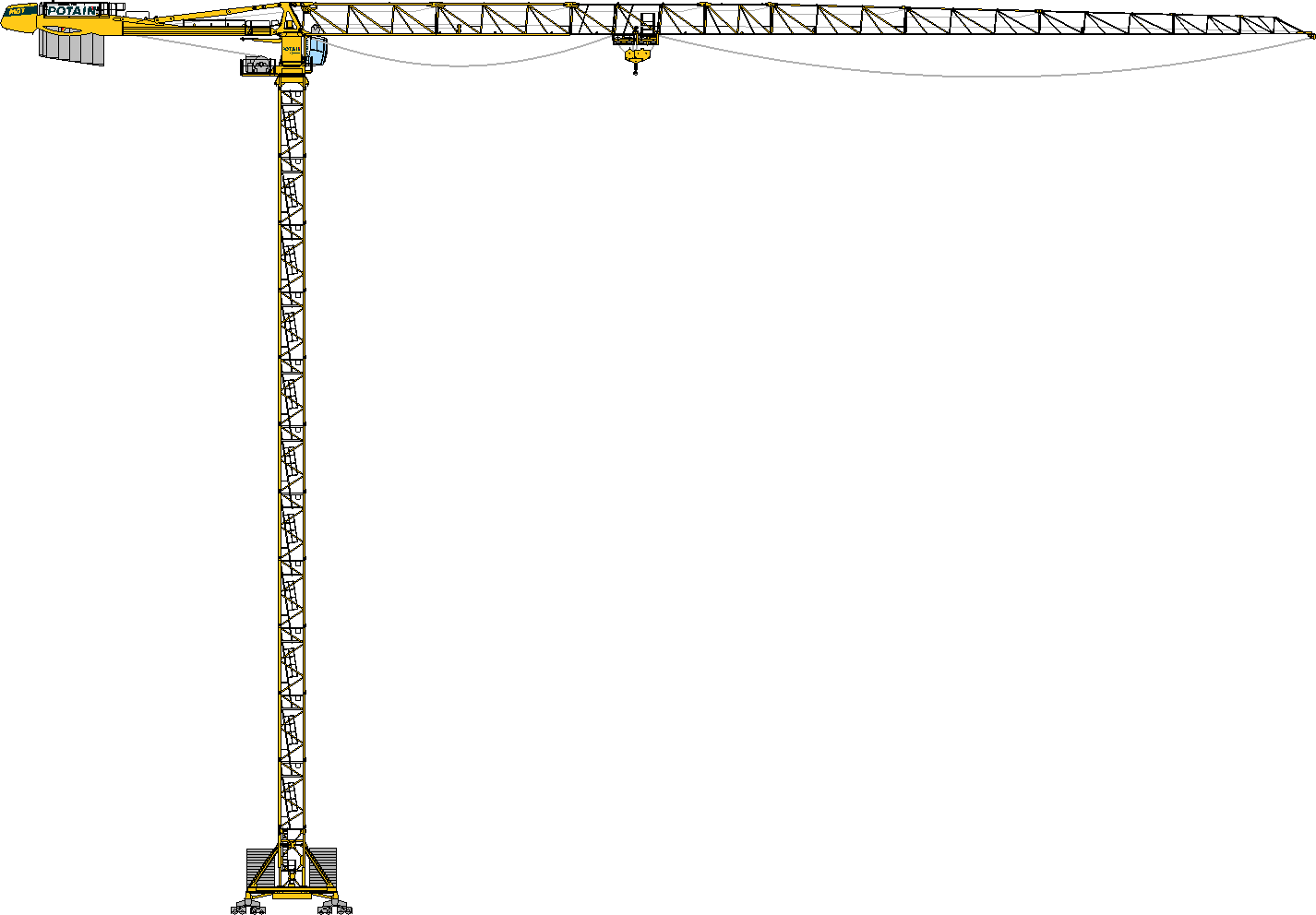

- There are 17 Potain MDT series topless tower cranes operating across various sites: 11 MDT 219s, four MDT 319s, and two MDT 389s.

- Italian contractors CMB long-time Potain partners and Renco Group, are handling the lifting work on the project.

Located on the northwest edge of Milan, the MIND project covers nearly one million square meters — approximately the size of 120 football fields. The €4.5 billion project is meant to construct “the city of the future,” a fully decarbonized district designed for connectivity, inclusion, culture and well-being.

Two Italian construction firms with deep ties to Potain are leading the work: Renco Group and CMB (Cooperativa Muratori e Braccianti di Carpi). Combined, they are using 17 Potain MDT topless cranes across the development. The cranes’ topless design, high load capacity, and ease of transport make them ideal for dense, multi-contractor environments like MIND.

MIND is comprised of several separate construction projects, and two contractors are handling the lifting work on various sites.

CMB is managing several of the job sites, including MoLo — a mobility and logistics hub with 1,800 parking spaces — and the mixed-use Horizon and Zenith towers. At nine and 13 stories, respectively, the towers combine concrete and timber construction to reduce environmental impact and carbon emissions. Zenith will become Italy’s tallest timber building.

Simone Motta, project manager at CMB, said the company relies entirely on five Potain MDT topless cranes for its operations at MIND: three MDT 319s at Horizon, and an MDT 319 and MDT 389 at the Zenith building.

“From an execution standpoint, these buildings are designed with prefabrication in mind — to accelerate construction and reduce on-site labor while minimizing potential risks,” Motta explained. “We chose to use only Potain MDT cranes, which required a careful analysis of logistics, operating radii, and potential interferences. That planning allowed us to achieve optimal coverage of the entire construction area. The cranes were essential for assembling floor slabs and façade panels throughout the process.”

Nearby, Renco Group is managing the construction of a new University of Milan campus, scheduled for completion in 2027. It includes 18,000 m2 of classrooms, 35,000 m2 of laboratories, and spaces for recreation and green living, including a botanical garden and sports areas.

The company is using 11 MDT 219 cranes in varying configurations, supported by an additional MDT 389 erected at 75 m for the heaviest lifts. The MDT cranes’ Crane Control System (CCS) and easy transport configuration have proven valuable on the dense urban jobsite.

Andrea Salaroli, project manager at Renco, explained how the company is using the 12 cranes for its part of the MIND project.

“Given the scale and complexity of the site, we developed a lifting plan with Potain that includes twelve cranes,” Salaroli said. “This setup provides full coverage across the site and allows us to organize work in two shifts, accelerating progress.”

Nearby, Renco Group is managing the construction of a new University of Milan campus, scheduled for completion in 2027. It includes 18,000 m2 of classrooms, 35,000 m2 of laboratories, and spaces for recreation and green living, including a botanical garden and sports areas.

The company is using 11 MDT 219 cranes in varying configurations, supported by an additional MDT 389 erected at 75 m for the heaviest lifts. The MDT cranes’ Crane Control System (CCS) and easy transport configuration have proven valuable on the dense urban jobsite.

Andrea Salaroli, project manager at Renco, explained how the company is using the 12 cranes for its part of the MIND project.

“Given the scale and complexity of the site, we developed a lifting plan with Potain that includes twelve cranes,” Salaroli said. “This setup provides full coverage across the site and allows us to organize work in two shifts, accelerating progress.”

Nearby, Renco Group is managing the construction of a new University of Milan campus, scheduled for completion in 2027. It includes 18,000 m2 of classrooms, 35,000 m2 of laboratories, and spaces for recreation and green living, including a botanical garden and sports areas.

The company is using 11 MDT 219 cranes in varying configurations, supported by an additional MDT 389 erected at 75 m for the heaviest lifts. The MDT cranes’ Crane Control System (CCS) and easy transport configuration have proven valuable on the dense urban jobsite.

Andrea Salaroli, project manager at Renco, explained how the company is using the 12 cranes for its part of the MIND project.

“Given the scale and complexity of the site, we developed a lifting plan with Potain that includes twelve cranes,” Salaroli said. “This setup provides full coverage across the site and allows us to organize work in two shifts, accelerating progress.”

Once complete, the Milan Innovation District will feature Europe’s longest linear park — spanning 460,000 m2 — with 3,000 new trees, 4 km of bike lanes, and a fully electric internal transport network. For CMB and Renco, Potain cranes are helping bring this sustainable vision to life.

“Potain cranes have always delivered the reliability and precision we need on complex urban projects,” Salaroli said. “ At MIND, that dependability is helping us meet ambitious goals and build the next generation of Milan.”

CONTACT

Dominique Leullier

Marketing Director Europe

Manitowoc

T +33 4 72 18 20 20

dominique.leullier@manitowoc.com

Features

Crane Control System (CCS)

Manitowoc Crane Control System (CCS) – Offers a user-friendly interface, full graphic display, ergonomic controls, a jog dial for easier navigation and data input, and parts commonality across Grove, Manitowoc and Potain product lines enhancing operator familiarization and serviceability.

POTAIN

Top-Slewing Cranes

Top-Slewing cranes are the large construction sites most strategic equipment for productivity. Whether on large infrastructure, high rise jobsites, crowded urban areas or wide open sites, they make it possible to hoist and distribute loads high and far. The Potain brand is a global leader with its multiple ranges of topless cranes, luffing jib cranes and large hammerhead cranes that can also be customized to match special applications.