Four Potain cranes drive progress at Torre Faro in Milan for energy company A2A

- Contractors CMB and Colombo Costruzioni teamed up on the project, each bringing two cranes.

- CMB supplied a newly acquired MDT 349 L16 and MDT 219 J10, while Colombo deployed an MD 208A and another MDT 349 L16 from its fleet.

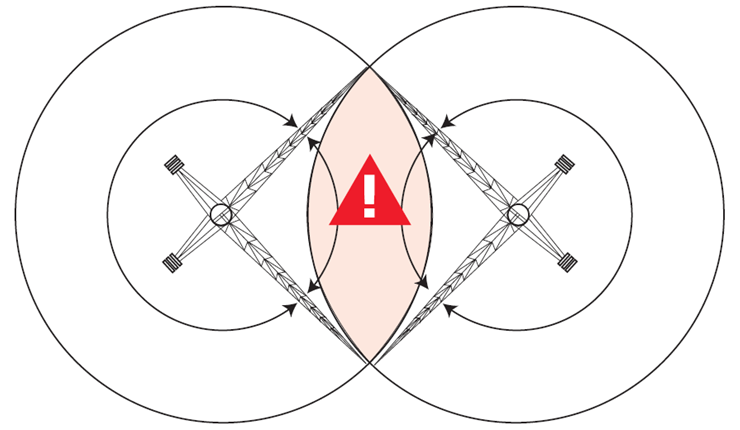

- Given the tight operating conditions, the Top Tracing 3 anti-collision system plays a crucial role in ensuring operations run smoothly.

Four Potain tower cranes from two of Manitowoc’s long-time Italian partners are working on Milan’s prestigious Torre Faro (Lighthouse Tower), scheduled for completion later this year. Leading contractors CMB Cooperativa Muratori e Braccianti di Carpi and Colombo Costruzioni have teamed up, each deploying two cranes and providing in-depth knowledge of BIM technology for the 144 m skyscraper for A2A, one of Italy’s biggest energy and environmental groups. To meet the ambitious construction schedule, the cranes are working in close proximity, with Manitowoc Lift Solutions providing detailed consultancy on the positioning.

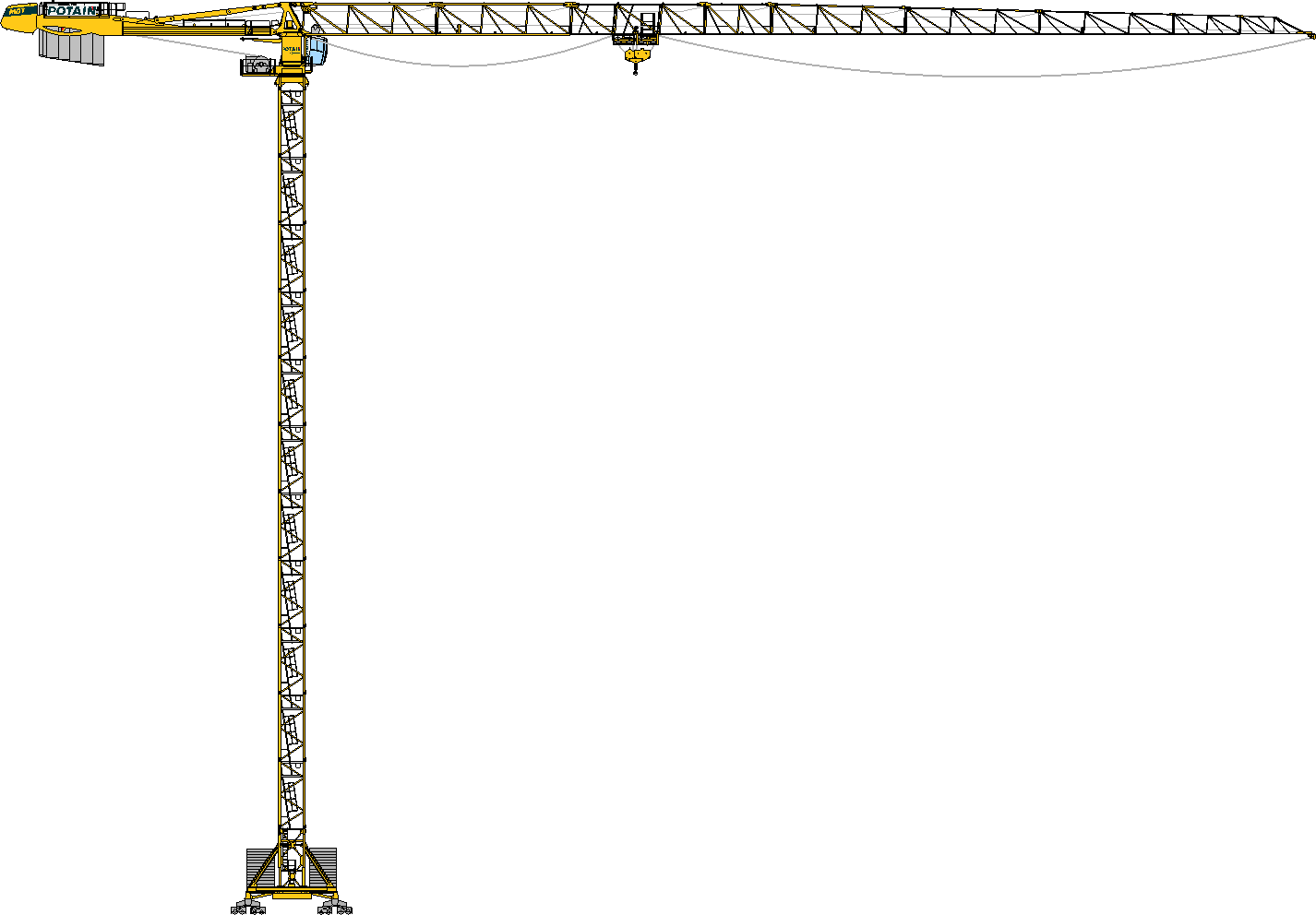

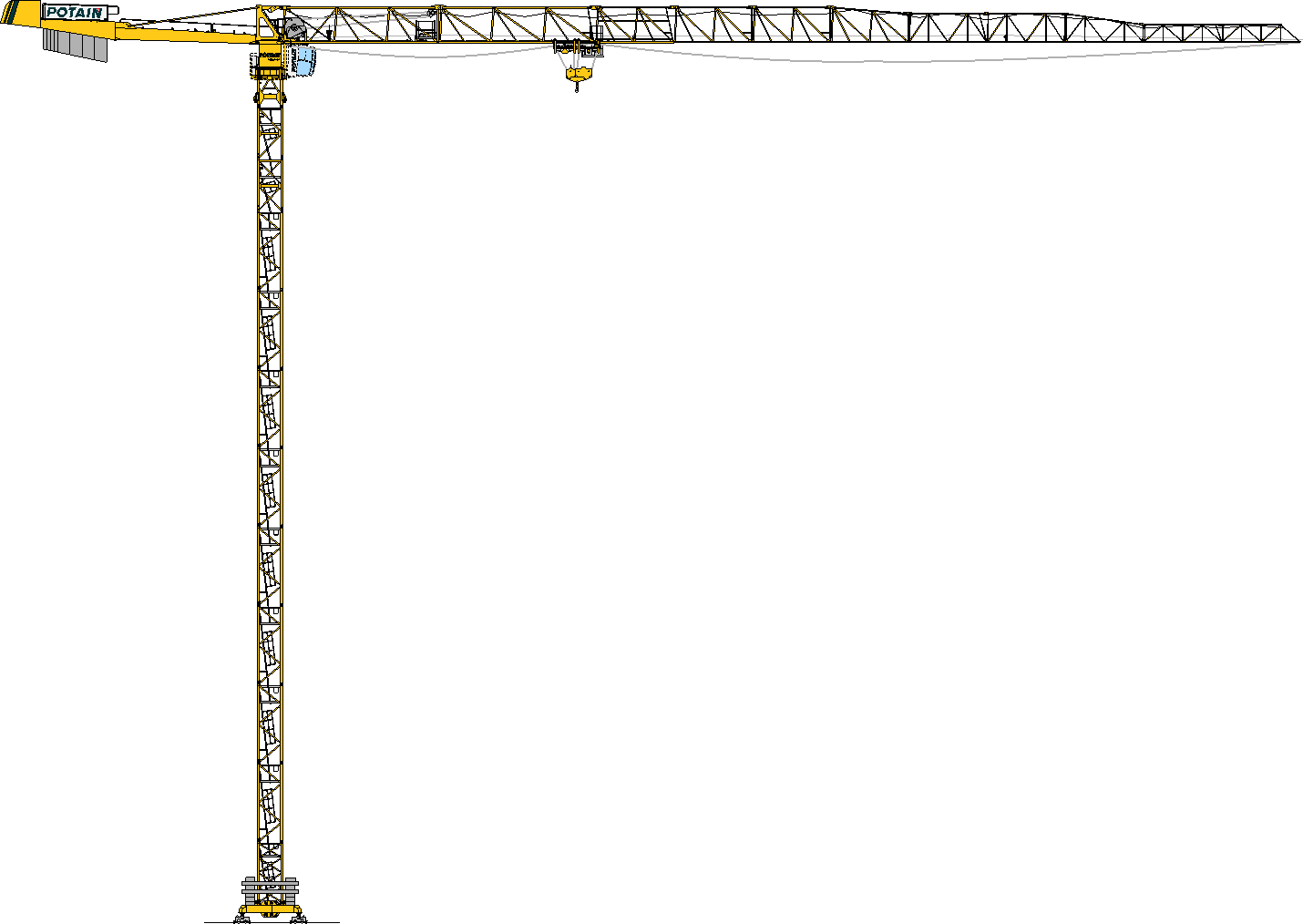

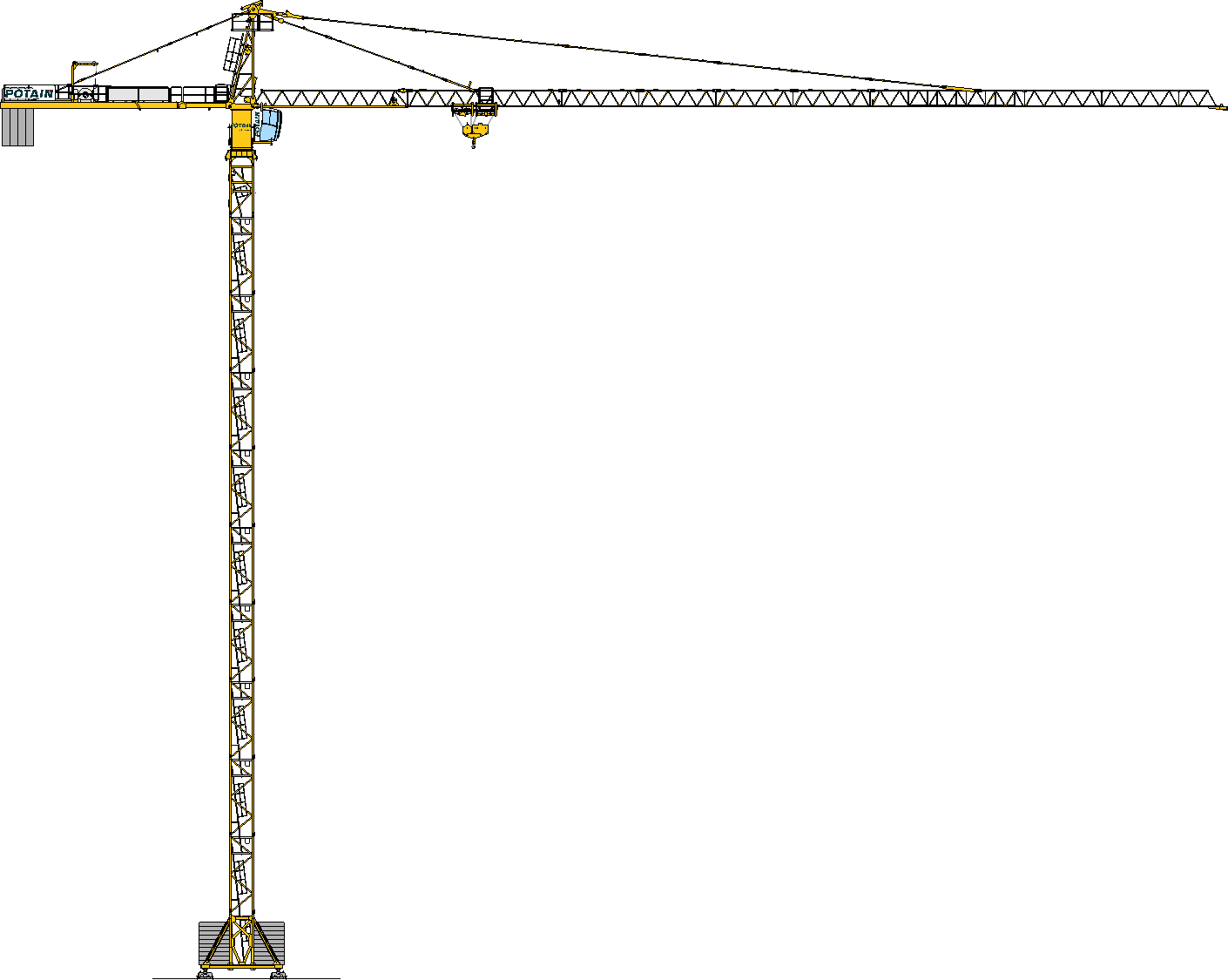

CMB acquired two new cranes for the project – an MDT 349 L16 and an MDT 219 J10, both of which have access to the Potain CONNECT™ telematics platform. Colombo provided an MD 208A and MDT 349 L16 from its fleet. Both the MDT 349 cranes are working with 45 m of jib and will eventually reach heights under hook of 158.6 m and 168.8 m. The other two models will remain freestanding, with the MD 208 A reaching a height under hook of 61.4 m and working with a 35 m jib, and the MDT 219 reaching 39.8 m height under hook and working with a 50 m jib. The four cranes are lifting materials weighing up to 4 t.

“After detailed analysis, the cranes were set up very close to each other to achieve maximum efficiency. We are using Potain’s Top Tracing 3 anti-collision system to ensure everything runs smoothly,” said Matteo Pastore, head of Lift Solutions at Manitowoc in Italy. “Top Tracing 3 enables remote supervision via a laptop of up to 16 cranes and 30 work areas simultaneously, so we can avoid the risk of interference. Using three topless cranes on this job also made it easier to have them working closely together.”

A2A’s new headquarters reflects its vision for a greener Milan, focusing on benefits to the local community through lower environmental impact. The new building is expected to achieve a 30-35% reduction in energy and water consumption through geothermal heating and cooling technology, solar panels, and rainwater collection systems. A Sky Garden on the 12th floor features hanging gardens and a panoramic viewing platform open to the public will offer breathtaking views of Milan.

“We chose these cranes because they offer excellent capacity and working height, along with ease of movement, and faster, more assured movements,” said Gianluca Arconi, Colombo Costruzioni’s technical director. “Add in the intuitive Crane Control System (CCS) and you have an ideal package for complex projects in urban environments.”

CMB and Colombo Costruzioni have more than 120 years of combined experience in the construction sector, and the two contractors have delivered many of Milan’s most impressive towers, including their recent collaboration on the striking Citywave project.

CONTACT

Dominique Leullier

Marketing Director Europe

Manitowoc

T + 33 4 72 18 21 60

dominique.leullier@manitowoc.com

Features

Top Tracing 3

Anticollision System - Device for controlling working zones and interference between cranes.

POTAIN

Top-Slewing Cranes

Top-Slewing cranes are the large construction sites most strategic equipment for productivity. Whether on large infrastructure, high rise jobsites, crowded urban areas or wide open sites, they make it possible to hoist and distribute loads high and far. The Potain brand is a global leader with its multiple ranges of topless cranes, luffing jib cranes and large hammerhead cranes that can also be customized to match special applications.